Brenneke Website

Chuck Hawks

Giro Slugs

|

|

|

|

|---|

|

Brenneke Website Chuck Hawks Giro Slugs |

Fourten Calibre Giroslug

|

|---|

The rifled slug is not a new development, but the version described here has considerable differences in design concept to those that are already in common use.

The .410 version of this projectile has a page to itself, as the shape is not quite the same as the larger calibre versions. The .410 case, being longer in relation to it's diameter, lends itself to a longer, more streamlined, shape than the larger shotgun calibres. The original development and experimentation was carried out at .32 calibre using projectile shapes more akin to the .410 type than the larger calibres, whose shape was extrapolated on a drawing board, rather than direct development.

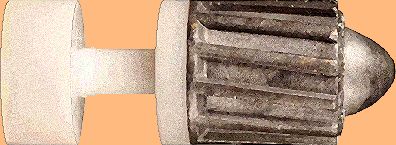

| The Brenneke version of the .410 rifled slug along with it's wad, is illustrated at right for comparison purposes. It is the most well know of it's type and has deep external spiral grooves on it's surface that are intended to impart spin to provide gyro stabalisation in the way that a rifled barrel does, but rifling the projectile does not impart as much spin as most designers hoped for. |

|

|---|

To understand why it is not as effective as was first thought, we must realise that the airstream is being parted by the relatively blunt front of the slug, which means that the winged grooves have very little effect as there is no container to constict the air flow along the grooves.

|

I initially thought (1969) that I could improve the situation by turning the

rifled slug

concept 'inside out' and creating a smooth outer cylindrical projectile that had fins

rather like a turbine fan on the inside of the cylindrical surface, the airflow over the

fins being vented at the rearmost part of the lead alloy portion with an angled exit to the

vents. The wad would be cylindrical as well without a waist. By these means I was hoping

that the spin rate may be improved and at the same time the lower turbulance would be

helpful in maintaining projectile velocity. The hollowness of the interior was also thought

to offer expansion properties that would be useful in producing shock at the point of

impact. Although I played around with the idea in sketch form for several years, I never

got this project off the ground as far as prototype slugs, so no testing was ever done on

the idea (I was also a little sceptical of the turbulance that might be caused by the

angled jets of gas exiting from the sides of the cylinder.)

Now consider the un-broken airflow over the smooth contoured bulbous aerofoil shape shown at right. The flow over this teardrop shape is smooth (lamina flow) and although there is still air resistance (but much lower resitance than the finned slug) there is no turbulance at all. That is simple aerodynamic theory, but the shape is rather difficult to consider as a projectile to be fired from a shotgun cartridge. We cannot use the shape directly, but we can bear it in mind and strive towards it during the rest of the design process. Our cartridge projectile needs extra features, these are...

|

Now we can expand on our ideas a little... We can consider the basic teardrop

shape as a goal, but this has to fit into the frontal portion of a cartridge case, so we

have some limits that are illustrated in the sketch at right. When we consider the position

intended for the

obturator wad (shown pink), it, along with the front portion of our teardrop, is

reminiscent of the shape of a bomb of the type usually dropped from WW II aircraft.

Such bombs had fins at the rear which were used for stabilisation and sometimes these fins

were angled in order to produce spin stabilization. We may be able to make use of this as

the airflow over our teardrop is lamina and is in the right directon to cause maximum

effect on any fins.

Now we can expand on our ideas a little... We can consider the basic teardrop

shape as a goal, but this has to fit into the frontal portion of a cartridge case, so we

have some limits that are illustrated in the sketch at right. When we consider the position

intended for the

obturator wad (shown pink), it, along with the front portion of our teardrop, is

reminiscent of the shape of a bomb of the type usually dropped from WW II aircraft.

Such bombs had fins at the rear which were used for stabilisation and sometimes these fins

were angled in order to produce spin stabilization. We may be able to make use of this as

the airflow over our teardrop is lamina and is in the right directon to cause maximum

effect on any fins.

Our selected streamlined shape does not have a flat portion that a rolled turnover can be applied to, but we can create a tighter than normal crimp, the roll of which will retain the slug with a portion of it's nose sticking out of the mouth of the cartridge, such a frontal appearance leaves no doubt as to the actual cartridge load, so no further identification is necessary.

The pointed tail of the teardrop shape is not feature of the actual projectile, but is included to show the stages of thinking in the development process.

Much of the development of this type of projectile was carried out at .32 calibre using a smooth bored barrel in a Lee Enfield No.4 action and modified .303 British cases. For further details consult the page... Giro Slugs.

Originated... 23 June 2007, Code Altered... 18 May 2008,

|